RESOURCES |

Category: Refining

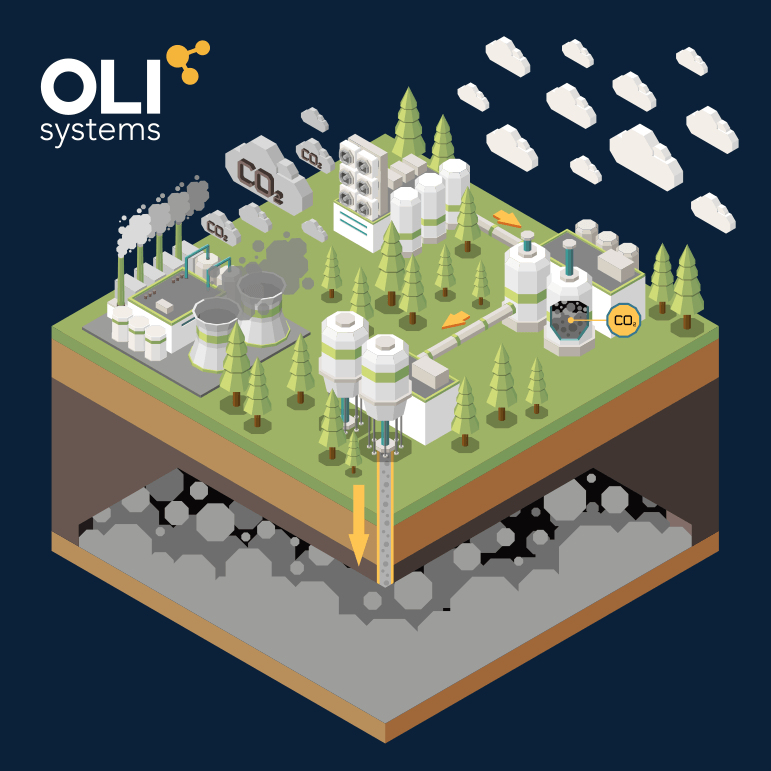

The transportation of carbon dioxide (CO2) plays a crucial role in combating climate change by supporting carbon capture and storage (CCS) projects and decarbonization initiatives. As the industry continues to grow, it presents opportunities and challenges for key players, particularly in the pipeline sector. This blog post explores the drivers behind the growth of the CO2 transportation industry, the challenges it faces and how asset integrity of pipelines can be enhanced.

Key Drivers: Decarbonization utilizing CCS

Two key drivers fueling the growth of the CO2 transportation industry are carbon capture and storage (CCS) and decarbonization initiatives. CCS technologies capture CO2 emissions and require infrastructure to transport the captured CO2 from emission sources to storage sites. Additionally, governments and industries are committed to decarbonization goals, leading to increased investments in carbon capture technologies and a surge in demand for CO2 transportation.

According to a recent estimate by the US Department of Energy Fossil Energy & Carbon Management (FECM) Office, the miles of pipeline required to transport CO2 will need to increase approximately 5 times from 5,300 miles today to 25,000 by 2050 to achieve the U.S. decarbonization goals. This same group estimates that the CO2 commercial storage capacity needs to grow from approx. 250 million MT in 2025 to over 30 billion MT by 2050 representing a 100 times increase. The ability to develop robust solutions to address this dramatic growth in CO2 transportation and storage is critical to making carbon capture a reality.

Role of Oil and Gas Companies in CO2 Transportation: Pipeline Infrastructure and Expertise

Oil and gas companies with expertise in pipeline infrastructure play a significant role in CO2 transportation. They are investing in repurposing existing pipelines or constructing new ones to transport captured CO2. Engineering and construction firms also contribute by providing the expertise needed for safe and efficient CO2 transportation infrastructure.

Unlocking the Potential: Impact on the Pipeline Sector and Technological Advancements

The growth of the CO2 transportation industry presents both opportunities and challenges for the pipeline sector. Repurposing existing pipelines for CO2 transport can reduce costs and environmental impact, providing new revenue streams for pipeline operators. Moreover, the industry’s growth will necessitate the construction of new pipelines, offering opportunities for pipeline companies to participate in the design, construction and operation of CO2 transportation networks. Technological advancements, such as advanced monitoring systems and leak detection techniques, will drive innovation in the pipeline industry.

Navigating Challenges in CO2 Transportation: Infrastructure, Regulations and Technical Solutions

The CO2 transportation industry faces challenges related to infrastructure development and regulatory frameworks. Constructing an extensive and interconnected pipeline network requires substantial investments and careful planning. Additionally, the industry must navigate specific regulations and policies governing safety, environmental impact and storage site selection.

The transportation of CO2 poses technical challenges that must be addressed for safe, efficient and cost-effective operations. High pressure and density of CO2 require robust pipeline materials and careful pipeline design. Corrosion and material compatibility issues arise, demanding advanced corrosion-resistant materials and coatings. However, corrosion resistant alloys can be cost prohibitive and often not economically viable. This makes it critical to understand how to optimize the use of carbon steel pipes and identify safe limits to mitigate corrosion risk. In conjunction with an understanding of the corrosion mechanisms, pipeline monitoring and leak detection technologies can help to enhance infrastructure integrity. Additionally, injection and storage challenges in underground geological formations require reliable and cost-effective solutions.

Mitigating Corrosion in CO2 Transportation

Corrosion is a significant concern in CO2 transportation. Pure carbon dioxide is not corrosive. However, the reason for the possibility of corrosion is the fact that the captured CO2 is never pure. It always contains some impurities that result from prior combustion and capture processes. Such impurities include various nitrogen oxides, sulfur oxides, hydrogen sulfide, oxygen and water. These impurities can react and form highly corrosive acids or elemental sulfur. The acids can form in minute quantities compared to the huge amounts of CO2, but they are extremely aggressive to carbon steel and can lead to catastrophic failure of the pipelines or tanks.

Corrosion inhibitors, coatings and linings and material selection offer effective solutions with their respective strengths and benefits. Ongoing research to better understand the underlying corrosion mechanisms, improved monitoring and inspection techniques, robust regulatory standards and collaboration among industry experts are necessary to enhance pipeline integrity and corrosion mitigation measures.

From a materials selection standpoint, corrosion-resistant alloys are expensive and can probably be used only for very short pipelines, while carbon steel is the only economically realistic alternative for long pipelines. Therefore, carbon steel appears to be the best choice for the transportation of CO2. Faced with this constraint, avoiding corrosion of carbon steel due to the formation of acids is critical to pipeline integrity. This makes the definition of safe limits for specific impurities extremely important. If the concentrations of the impurities can be kept below the safe limits, pipeline integrity can be maximized. In addition, these impurities do not have to be removed through costly cleaning procedures increasing operations efficiency.

Process Simulation: Innovating Asset Integrity and Cost Reduction in CO2 Transportation

OLI Systems, is leading the charge when it comes to R&D innovation to improve asset integrity and lower costs for CO2 transportation. OLI offers powerful tools to address corrosion-related concerns in CO2 transportation. Its process simulation capabilities allow accurate modeling and prediction of corrosion behavior, considering factors like temperature, pressure, flow rates and impurities. The software helps identify areas prone to corrosion, evaluate corrosion control strategies, optimize process conditions and enhance asset integrity.

The reactions that lead to the formation of acids and/or elemental sulfur are electrolyte reactions. The ability to predict the conditions under which the impurities can react and under which conditions they will remain innocuous is key to corrosion mitigation. The conditions include the various combinations of impurities and their concentrations as well as pressure and temperature. OLI uses the ability to predict these conditions to determine the safe limits for transportation.

OLI collaborated with the Norwegian Institute for Energy Technology (IFE) as part of a consortium of oil and gas and metal manufacturing companies in a project funded by the Norwegian Research Council to develop a methodology for predicting when the impurities will pose a danger to the integrity of CO2 transportation facilities. IFE’s world-leading experimental facilities were used to investigate the chemical and phase behavior of impurities in CO2. OLI combined its expertise in electrolyte thermodynamics with the experimental data generated by IFE to develop an accurate thermodynamic model for predicting the formation of corrosive components. This is currently available in the OLI software both in the desktop tools as well as in the Cloud platform.

Challenges, Opportunities and Technological Solutions for Climate Change

The transportation of CO2 is a crucial aspect of global climate change mitigation efforts, driven by CCS projects and decarbonization initiatives. Key players, such as oil and gas companies and engineering firms, will shape the industry’s development, but they must overcome challenges like infrastructure development including the associated technical challenges as well as regulatory frameworks. The pipeline industry will see significant impacts, with opportunities for repurposing existing infrastructure and expanding networks. Technological advancements will drive innovation, ensuring safe and efficient CO2 transportation. Overcoming technical challenges, such as corrosion, is crucial for the success of CCS projects. Ongoing research and collaboration are developing solutions, including advancements in pipeline materials, corrosion protection, monitoring systems and injection technologies. Implementing corrosion inhibitors, coatings and material selection can address corrosion challenges.

OLI Systems process simulation capabilities can accurately model corrosion behavior, enabling operators to mitigate corrosion risks, optimize system design and operation and ensure the safe transportation of CO2. Collaboration, research advancements and effective corrosion control strategies are necessary for a sustainable future and reduced greenhouse gas emissions.