Scale formation in geothermal systems occurs when the concentration of dissolved ions in produced geothermal fluids exceeds the solubility limits of certain minerals, resulting in the precipitation of solids, commonly referred to as scale. This phenomenon poses a significant challenge to geothermal operations, as scale can precipitate in various parts of the system, leading to severe operational issues such as formation damage, pipe restrictions, reduced heat exchanger performance, filter clogging, and decreased well injectivity. Understanding the mechanisms and chemistry behind scale formation is crucial for developing effective strategies to mitigate these challenges and ensure the efficiency and longevity of geothermal systems.

Mechanisms of Scale Formation

The formation of scale in geothermal systems is primarily driven by two key mechanisms:

- Mixing of Incompatible Waters: When waters with different chemical compositions mix, the equilibrium of dissolved ions can be disturbed, leading to the precipitation of minerals. This process is often observed when fluids from different geothermal reservoirs, or from different stages within the same reservoir, interact.

- Self-Scaling Due to Temperature and Pressure Changes: Geothermal fluids experience significant variations in temperature and pressure as they move from the reservoir to the surface. These changes can cause dissolved minerals to become supersaturated and precipitate as scale. The following are some specific examples of scale formation:

- Calcite Formation (CaCO3): Calcite scale commonly forms when pressure is reduced in the system, causing acid gases such as CO2 to be released. This release increases the pH of the fluid, thereby decreasing calcite solubility and leading to its precipitation.

- Silicate Scale Precipitation: Silicate scales, often amorphous in nature, can form as the produced geothermal fluids cool. These scales are particularly challenging to manage due to their complex chemistry and tendency to form under a wide range of conditions.

- Barite Formation (BaSO4): Barite scale can precipitate either due to the mixing of incompatible waters or because of temperature decreases from reservoir to topside conditions, which reduce the solubility of barite.

Challenges in Predicting and Controlling Scale Formation

Despite significant advancements in geothermal research and technology, predicting and controlling scale formation in geothermal systems remains a complex and unresolved challenge. While the thermodynamics of minerals like calcite and barite are well understood, several factors complicate the prediction and management of scale.

- Complex Kinetics and Crystal Growth Dynamics:

Although the fundamental thermodynamics of calcite and barite formation are established, the kinetic processes governing their crystal growth, deposition, and detachment from surfaces are not as thoroughly understood. These kinetic factors, including the rate at which crystals form and grow under varying geothermal conditions, can significantly impact scale formation but are difficult to predict accurately. - Challenges with Silica Scale Formation:

Silica scaling presents particularly tough challenges due to the complex nucleation, polymerization and colloid particle formation in aqueous solutions as well as surface deposition. Additionally, the presence of trace elements like iron (Fe), aluminum (Al), and calcium (Ca) can further complicate these processes. - Environmental and Economic Limitations of Chemical Inhibition:

While chemical inhibitors can mitigate scale formation in some geothermal systems, their application is often limited by economic and environmental considerations. The large volumes of chemicals required, coupled with the associated costs and potential environmental impacts, pose significant barriers to widespread use in geothermal operations. Moreover, not all inhibitors are equally effective across different types of scale, further limiting their utility. - Operational Adjustments as a Partial Solution:

Adjusting operating conditions, such as temperature and pressure, can sometimes help control the rate and location of scale deposition, making it more manageable. However, this approach is not universally applicable and can only be optimized through accurate fluid modelling. Precise modelling allows for the identification of the best operating windows and the evaluation of different strategies to minimize scale formation in specific geothermal systems.

In summary, while we have made strides in understanding the factors that contribute to scale formation, the intricate interplay of thermodynamics, kinetics, fluid chemistry, and operational conditions can still present significant challenges. Advanced scale prediction modelling is therefore essential for effective scale mitigation and management.

Importance of Reliable Modelling and Fluid Compositional Data

To effectively prevent and control scale formation, reliable modelling of the thermodynamics and kinetics of scale formation is essential. Such models provide critical insights into which types of scales are likely to form in a specific geothermal play, their potential locations within the system, and their quantities.

Moreover, accurate modelling provides an understanding of how fluids change from downhole to topside conditions and how the four-phase fluid equilibrium impacts compositions at sampling point.

OLI Studio: ScaleChem – State-of-The-Art Solution to Geothermal Scale Challenges

OLI Systems has spent over 50 years at the forefront of electrolyte modelling, delivering comprehensive, first-principle-based process modelling solutions for various applications, including geothermal energy production. OLI Studio: ScaleChem brings that expertise directly to geothermal operations, offering the most advanced tool for scale prediction and fluid composition profiling in geothermal systems.

OLI Studio: ScaleChem combines state-of-the-art thermodynamic and kinetic modelling to deliver accurate scale predictions, even in high-temperature and high-pressure environments with complex chemical compositions. Supported by the most extensive chemistry database in the industry and with an advanced model for silicates, the software offers reliable results across a wide range of geothermal conditions.

Key Benefits

- Predict and Prevent Scale: Anticipate scale formation, such as calcite, silica, or barite, to minimize downtime and reduce operational costs.

- Optimize Fluid Properties: Model fluid properties to improve system design and efficiency, maximizing output while lowering costs.

- Minimize Downtime: Accurate scale predictions lead to fewer disruptions and maintenance, ensuring smoother, cost-effective operations.

Real-World Application of OLI Studio: ScaleChem

In a practical application of OLI Studio: ScaleChem within a geothermal plant, a client operating a binary cycle power plant was experiencing persistent scaling issues in the pre-heaters and vaporizers. Despite the availability of some solid sample analyses, a comprehensive scale study was necessary to thoroughly investigate the issue and develop an effective solution.

Initial water sampling did not indicate a significant scaling risk, even though scale deposits were consistently found in most topside equipment. However, leveraging OLI’s expertise, the underlying causes were identified.

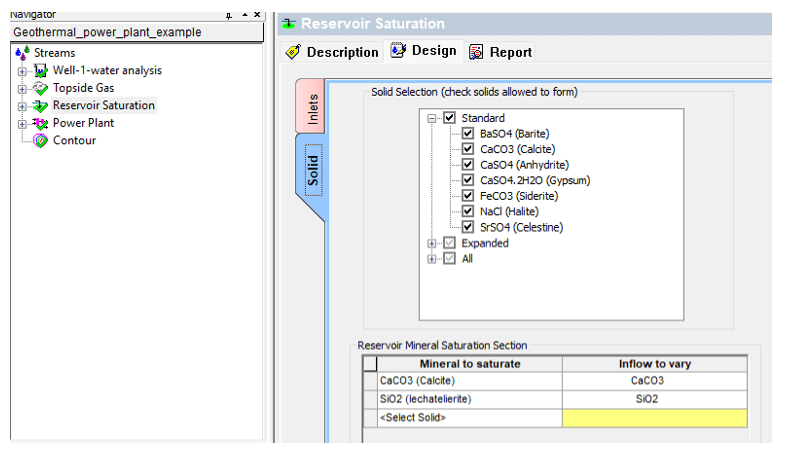

The process began with a fluid recombination to mix gas and aqueous phases at the sampling point’s temperature and pressure. This mixture was then equilibrated at reservoir conditions with calcite and silicates using the “Saturator” tool, simulating the mineral saturation levels typical in reservoir fluids.

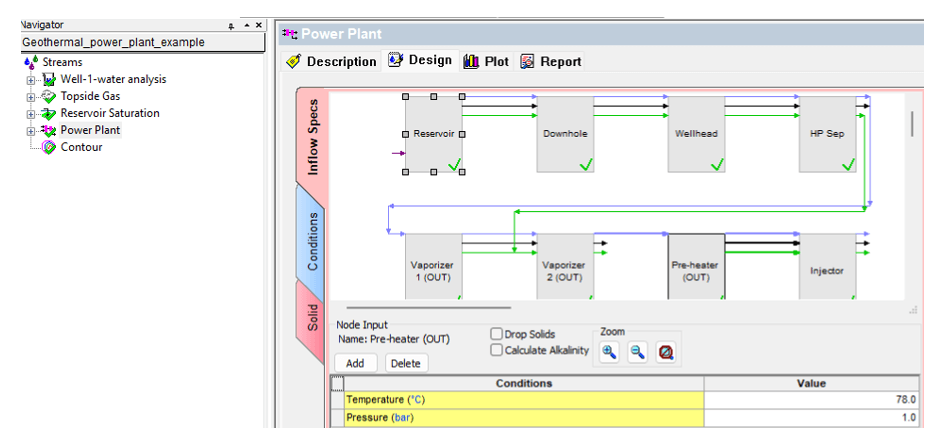

The fluid flow within the power plant was then accurately modelled using ScaleChem’s “Facilities” tool. The newly calculated representative total fluid composition was flashed at various temperature and pressure points to produce precise scale prediction profiles.

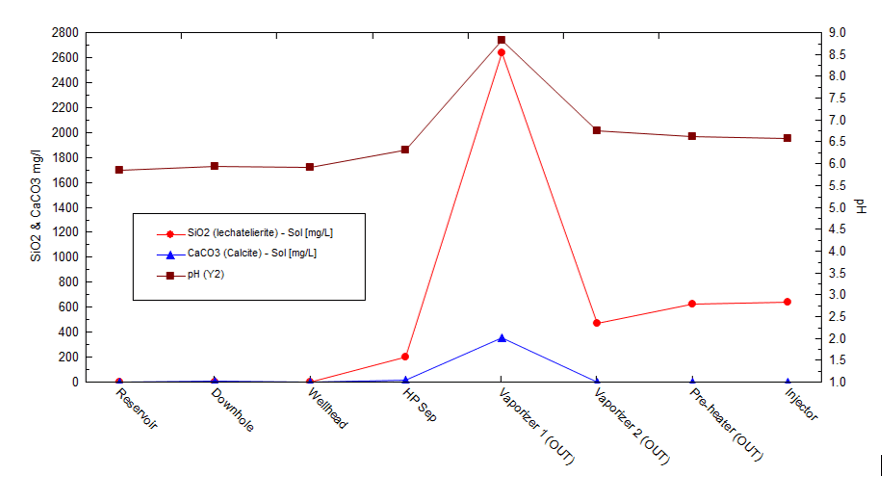

The analysis revealed a significant risk of silicate scale precipitation downstream of the separator and a high potential for calcite scaling in the first vaporizer. OLI Studio: ScaleChem also allowed for the tracking of pH, CO2, and alkalinity changes, providing insights into how these factors influence and are influenced by scale precipitation. Additionally, sensitivity studies were conducted to assess the impact of varying temperature and pressure on scale potential.

Notably, the calculated induction time for calcite precipitation indicated that the formation of this scale in the vaporizer was nearly instantaneous (2.1 second). The software will soon offer similar calculations for silicate scales as well.

This detailed and reliable scale study offered invaluable insights into the current scaling risks in this power plant and the effects of varying operational conditions on scale formation. With this information in hand, the operator was able to develop a targeted mitigation strategy, ultimately enhancing overall plant efficiency.

OLI Systems: Your Partner in Geothermal Success

At OLI Systems, we aim to be more than just a software provider. We understand the complexities of geothermal energy production and are here to help you navigate them. With OLI Studio: ScaleChem, you’ll have access to both our advanced tool and a team of experts ready to support your success.

- Unmatched Expertise: With over 50 years of experience in electrolyte modelling, our team is second to none. We’ve worked with some of the biggest names in geothermal energy, helping them solve their toughest challenges and achieve their most ambitious goals.

- Continuous Innovation: We’re always pushing the boundaries of what’s possible in scale prediction and fluid modelling. Our commitment to continuous innovation means you’ll always have access to the latest and most advanced tools, ensuring you stay ahead of the curve.

- Comprehensive Support: We’re with you every step of the way. From initial setup and training to ongoing support and updates, we provide the comprehensive support you need to get the most out of OLI Studio: ScaleChem.

Scale formation is a significant challenge in geothermal energy production, requiring a deep understanding of fluid chemistry, thermodynamics, and kinetics. While some progress has been made in predicting and managing scale, many complexities remain. Tools like OLI Studio: ScaleChem offer practical, data-driven solutions, enabling operators to predict, prevent, and manage scale more effectively. By leveraging advanced modelling, geothermal systems can operate more efficiently, reducing downtime, maintenance costs, and operational challenges.

Speak to an OLI expert today for tailored solutions that drive efficiency and reduce downtime.