In the oil and gas industry, operators managing onshore fields with thousands of wells face a multifaceted challenge: maintaining well integrity while balancing operational costs and ensuring production efficiency. Among these challenges, corrosion remains a silent yet critical threat that can undermine well performance and, if left unchecked, lead to costly failures.

Corrosion is a dynamic issue. Variations in water chemistry, flow rates, and pressure profiles introduce complexity to well management. As conditions evolve, traditional reactive approaches to corrosion mitigation often fall short, leaving operators struggling with unplanned maintenance and escalating costs.

Understanding the field-level perspective

Managing corrosion at a field level introduces a new dimension of complexity but also opportunity. Each well within a network exhibits unique conditions—variations in temperature, pressure, and water composition create localized hotspots for corrosion risks.

Without a comprehensive field-level view, identifying these hotspots and understanding their broader implications becomes challenging. For example:

- Water Chemistry Variations: Changes in ionic composition can influence corrosion risks and inhibitor performance, ultimately affecting well integrity.

- Corrosion Dynamics: General corrosion rates and localized corrosion propensity fluctuate with operational conditions, often in ways that are difficult to predict without advanced modeling tools.

A field-level understanding isn’t just about troubleshooting existing issues—it’s a cornerstone for strategic decisions. With the right tools, operators can select well materials tailored to local corrosion risks and estimate the lifecycle costs of treatments and interventions.

From reactive to proactive: How OLI corrosion cloud automation transforms oil well monitoring

OLI Systems’ Corrosion Cloud Automation tools are designed to address the complexities of modern well surveillance. Backed by decades of expertise in electrolyte thermodynamics and advanced modeling, these tools enable operators to understand corrosion risks in real time.

1. Real-Time monitoring of corrosion risks

At the core of OLI’s solution is the ability to continuously monitor key parameters that drive corrosion. This includes tracking corrosion rates, localized corrosion propensity, and water chemistry profiles across multiple wells.

The real-time monitoring capability offers an independent view of well dynamics, enabling operators to validate treatment plans and assess the effectiveness of current inhibitors. By identifying changes as they occur, operators can adjust treatment strategies proactively, rather than responding to failures.

2. Predictive modeling for proactive management

OLI’s tools integrate predictive modeling to simulate future conditions, allowing operators to anticipate risks before they manifest. Using first-principles electrolyte thermodynamics, these models account for variations in temperature, pressure, pH, and ionic concentrations, providing an accurate picture of how corrosion risks evolve over time.

Predictive insights are particularly valuable for long-term planning, such as determining the ideal material selection for new wells or refining treatment programs to balance cost and performance.

3. Field-level insights to pinpoint hotspots

A standout capability of OLI’s solution is its field-wide perspective. By aggregating data across a network of wells, operators can identify localized hotspots where corrosion risks are highest.

For example, changes in operating conditions, such as shifts in water cut or the production of variable water fractions, can impact brine chemistry and corrosion risks. Elevated corrosion rates in localized zones can point to operational adjustments needed to maintain well integrity.

4. Historical data integration for trend analysis

Historical data plays a pivotal role in understanding how wells behave over time. OLI’s tools enable operators to analyze cumulative corrosion impacts, track corrosion inhibitor effectiveness, and correlate field failures with predictive models. These insights provide a robust foundation for refining treatment plans and optimizing resource allocation.

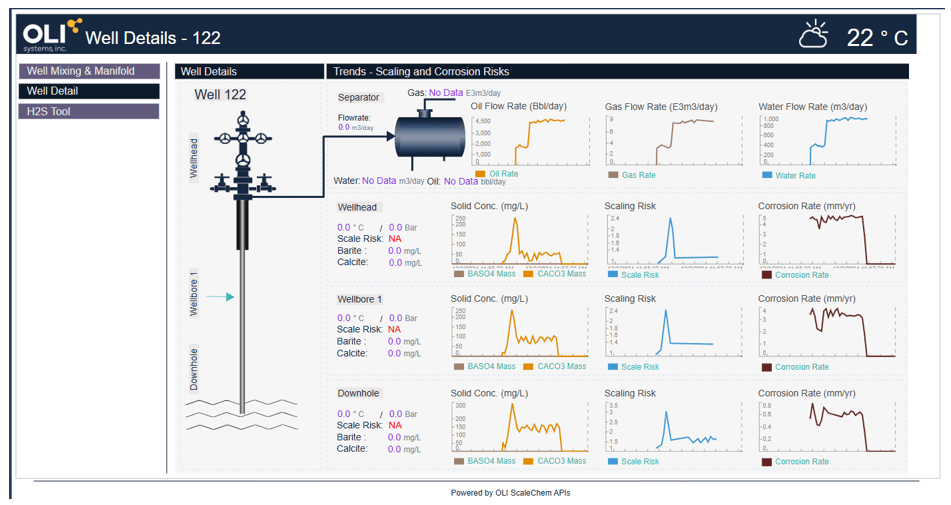

Figure 1: Corrosion Monitoring with OLI Cloud Solutions

The image illustrates a single well view connected to a centralized data platform powered by OLI Cloud Solutions. Key parameters such as corrosion rates and water chemistry profiles are highlighted, enabling operators to identify hotspots and implement proactive mitigation strategies.

A paradigm shift in corrosion management

What sets OLI apart isn’t just its technical capabilities but its holistic approach to corrosion management. By delivering modeling results that integrate seamlessly with customers’ existing visualization tools, OLI avoids adding another software to monitor while supporting centralized reporting.

Key advantages include:

- Workflow Integration: OLI tools fit into existing IT infrastructure, minimizing overhead and enhancing operational visibility.

- Access to Expertise: Operators benefit from a team of electrolyte chemistry specialists to maximize tool value.

- Secure Data Handling: SOC II compliance (U.S.-based) or compliance with other regulations worldwide ensures that sensitive operational data is well-protected.

Strategic decisions, informed by data

With a field-level understanding of corrosion dynamics, operators are better equipped to:

- Optimize Chemical Treatments: Adjust dosing rates based on real-time and predictive data for cost-effective mitigation.

- Select Materials Strategically: Choose materials tailored to local risks, extending equipment lifespan and reducing maintenance costs.

A partner in precision and innovation

OLI Systems is more than a software provider—it’s a partner in redefining how corrosion risks are managed in the oil and gas industry. By combining scientific rigor with practical tools, OLI empowers operators to transition from reactive problem-solving to proactive management strategies that drive long-term success.

Looking forward

As the oil and gas industry continues to evolve, the ability to manage corrosion risks proactively will define the difference between reactive operations and optimized performance. With OLI Corrosion Cloud Automation, operators have the tools they need to navigate these challenges, ensuring well integrity, reducing costs, and maintaining production efficiency.

Are you ready to transform your well surveillance strategy? Contact OLI Systems to explore how our Corrosion Cloud Automation tools can help you achieve proactive, data-driven well management.