In the dynamic landscape of modern industrial operations, effective corrosion management is crucial for ensuring the longevity and safety of our metal-based infrastructure and machinery. As industries strive for higher efficiency and extended asset life, the need for more sophisticated corrosion prediction tools has never been more critical. Yet, traditional models for predicting general corrosion rates and susceptibility to localized corrosion of metallic materials have often fallen short, especially in non-aqueous environments. With the launch of the V12 release, OLI Systems introduces a groundbreaking solution: the MSE corrosion model. This innovative model is set to transform the way industries predict and manage corrosion.

For decades, OLI’s AQ corrosion model has been instrumental in predicting corrosion rates and guiding material selection across various industries. The AQ corrosion model, however, relies on the presence of a water-rich phase within the system to predict accurate results. This requirement has restricted its application, particularly in environments where water is a minor component or entirely absent. Industries dealing with concentrated sulfuric acid, ethanol, supercritical CO2, or any other solvent have found these models less effective, leaving a significant gap in corrosion management strategies.

Introducing the MSE Corrosion Framework

To bridge this gap, OLI Systems developed the MSE (Mixed Solvent Electrolyte) corrosion model through extensive research and validation. This first-of-its-kind model was designed to predict corrosion under a broader range of process compositions and effectively eliminates the water-dependency barrier. By integrating OLI’s MSE thermodynamics framework with electrochemical kinetics, the model expands the boundaries of what is possible in corrosion prediction. This versatility makes it a powerful tool capable of managing a wide array of chemical environments and sets a new standard in corrosion prediction technology.

First Release and Its Capabilities

The first release of the MSE corrosion model as part of the V12 launch marks a significant milestone in the field of corrosion management and is a testament to OLI’s commitment to innovation. It provides general corrosion rate and localized corrosion rate predictions for two critical duplex stainless steel alloys, 2507 and 2205, which are extensively used across various industries due to their high strength and corrosion resistance.

V12 NOW AVAILABLE

Revolutionizing chemistry process simulation and modeling that enhances asset integrity, operational efficiency and optimization. Predict. Protect. Perform.

Download nowThe model assesses these alloys in different environmental conditions, considering factors such as oxygen levels, chloride concentrations, and the presence of reducing and oxidizing species, among others. This capability not only broadens our understanding of how these alloys will perform in harsh environments but also aids in improved material selection from the design phase onward. Looking ahead, OLI remains committed in its corrosion research to incorporate more complex environmental data and expand the range of materials covered.

Application Across Industries

The MSE Model’s ability to predict general and localized corrosion rates in water-depleted environments broadens its applicability across various industries. Key sectors that stand to benefit include oil and gas, chemical manufacturing, pulp and paper, CO2 injection, geothermal, and more.

Real-World Applications Across the Asset Lifecycle

The MSE corrosion model seamlessly integrates into every phase of an asset’s lifecycle, from initial design and material selection to ongoing maintenance and operational adjustments. For instance, in the refining industry, the model’s predictions can optimize the materials used in HF alkylation units, reducing downtime and preventing failures. In geothermal energy production, where chemistry can be particularly aggressive, MSE provides insights that can significantly extend the life of critical components. Similarly, in CO2 injection processes, where the chemistry may include supercritical phases with post-combustion impurities like NOx, SOx, and O2, the MSE Model provides invaluable data that can prolong the lifespan of critical infrastructure.

Advantages over alternatives

The MSE corrosion framework will be available through the Corrosion Analyzer software and can be used together with Stream Analyzer for corrosion predictions. This same functionality will also be available through the OLI Cloud Platform for automation applications.

OLI’s MSE corrosion model stands out from alternative models that require users to manually specify the chemical species involved in corrosion processes. In contrast, by design, the Corrosion Analyzer tool recognizes corrosive species from a stream’s inflows and calculates corrosion based on the participating reactions. It also calculates relevant bulk properties such as pH and diffusivities, offering a more comprehensive, accurate, and user-friendly approach. This unique capability not only predicts general corrosion rates but also provides localized corrosion indications, enhancing the reliability of the predictions and enabling industries to proactively manage corrosion risks.

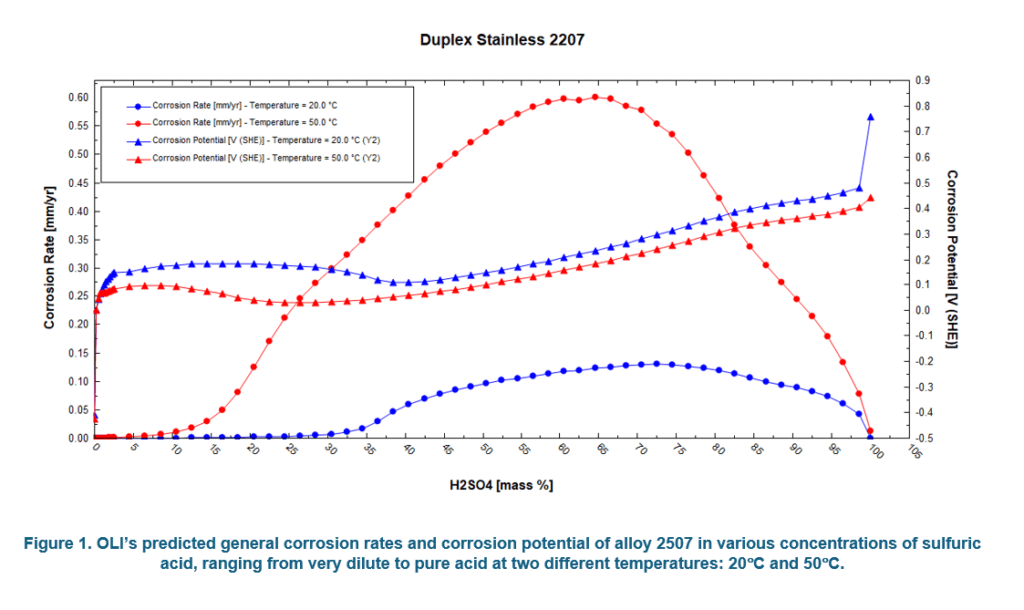

Figure 1 illustrates an output plot of the type of information that users can generate with the MSE corrosion framework in the Corrosion Analyzer. Figure 1 shows the predicted general corrosion rates and corrosion potential of alloy 2507 in different sulfuric acid concentrations, ranging from very dilute to pure acid. The model is capable of quantitatively predicting corrosion rates as a function of both temperature (20-50°C) and sulfuric acid concentration.

Looking ahead, OLI Systems plans to continually update and expand the MSE corrosion model. Future releases will include additional alloys and more complex environmental conditions, further enhancing the model’s applicability and accuracy. This ongoing development reflects OLI’s commitment to staying at the forefront of corrosion management technology, providing users with the tools needed to tackle emerging challenges.

Conclusion

The MSE corrosion model represents a significant advancement in the field of corrosion prediction. With its innovative approach and advanced capabilities, it is set to transform how industries manage and mitigate corrosion. As we move further into the era of Industry 4.0, tools like the MSE Model are crucial for ensuring the longevity and reliability of industrial assets.

We invite industry professionals, engineers, and maintenance managers to explore the potential of the MSE corrosion model. Discover how this cutting-edge tool can integrate into your operations to enhance safety, efficiency, and profitability. Contact our team for a detailed consultation and see what the MSE corrosion model can do for you. Contact us